Save fuel costs by correct

refractory selection.

Easy-to-use simplified software to calculate skin temperature of furnace and select most effective refractory configuration.

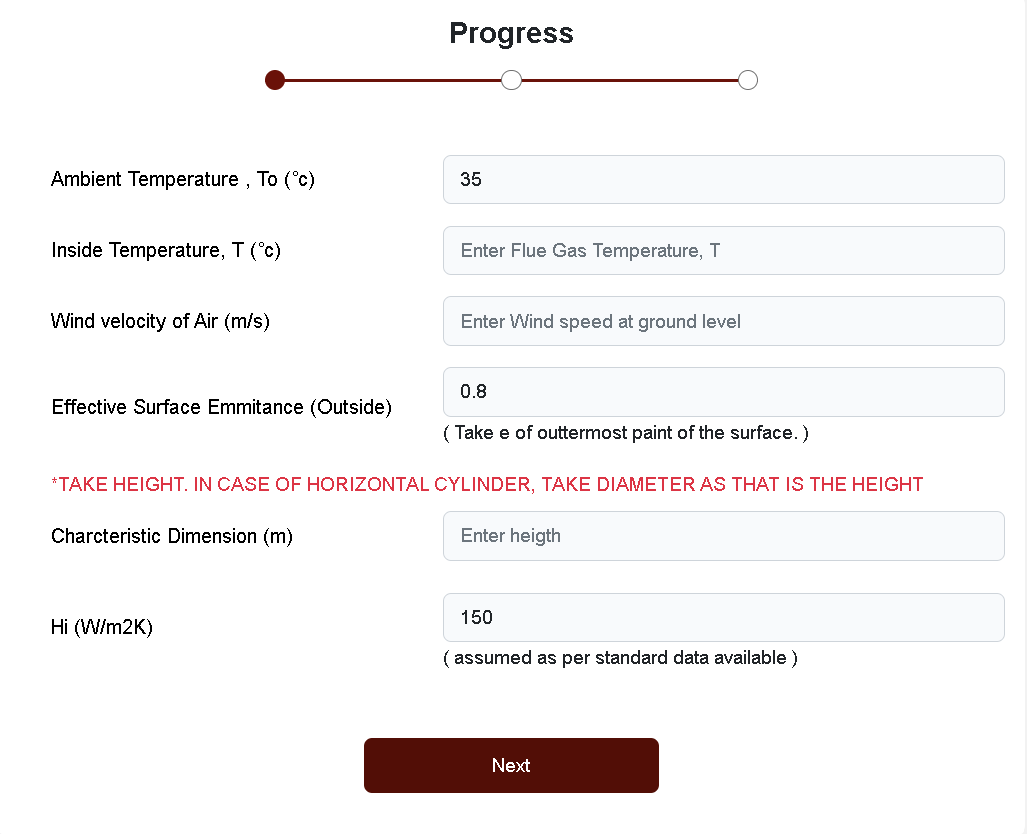

Site conditions

Define the site conditions

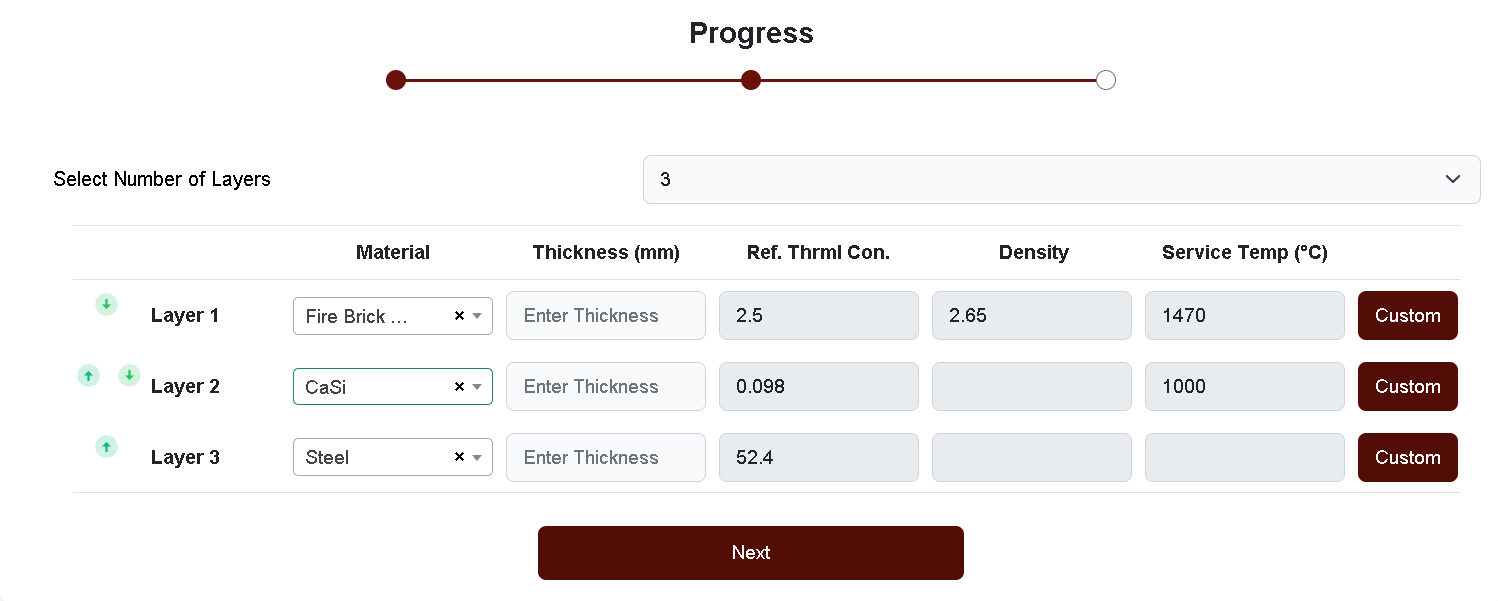

Select the refractory layers

Select, Size, Reorder the refractory layers

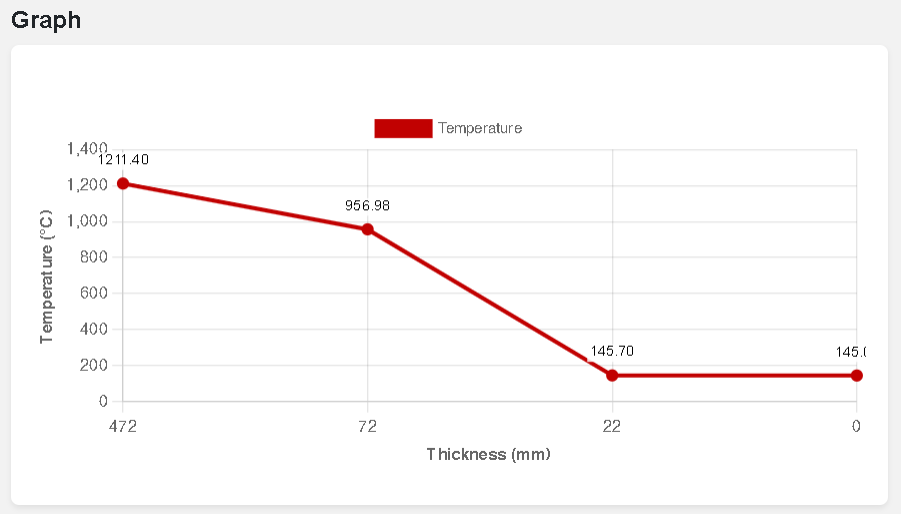

Results

Refractory thermal simulation is carried out. The skin temperature alongwith interface temperatures are calculated to evaluate the refractory selection

Testimonials

Refractory Thermal Simulation reviews

Project Engineer

“Super clean and easy to use. No training required.”

- Dev Patel

Sales Engineer

“Fast and easy to use software to quick identify best refractory selection”

- Laxmi

Executive

“Absolutely love the ease of refractory thermal simulation software.”

- Jayesh Singh

Design Lead

“Very fast and efficient way to configure best refractory layers selection which helps save costs for end-user.”

- Rakesh J

Plant manager

“Verified and found correct as per site condition.”

- Tilesh R.

Design executive

“Loved the rearrangment feature, which helps in optimising the refractory layers arrangement”

- Anish Patel

FAQ's

Looking for answers to your frequently asked questions? Check out our FAQ's section below to find.

Pricing Plans

Pay, only if needed

Starter

For individuals and small teams

Register NowBasic

For growing teams and startups

Contact SalesPrime

For enterprises and agencies

Contact SalesReady to start?

See how easy the softwares make the refractory selection calculations. Get started for free, no credit card required.

Try nowContact : info@refractorythermalsimulation.com

- Product by Mc Clelland Engineers Pvt Ltd